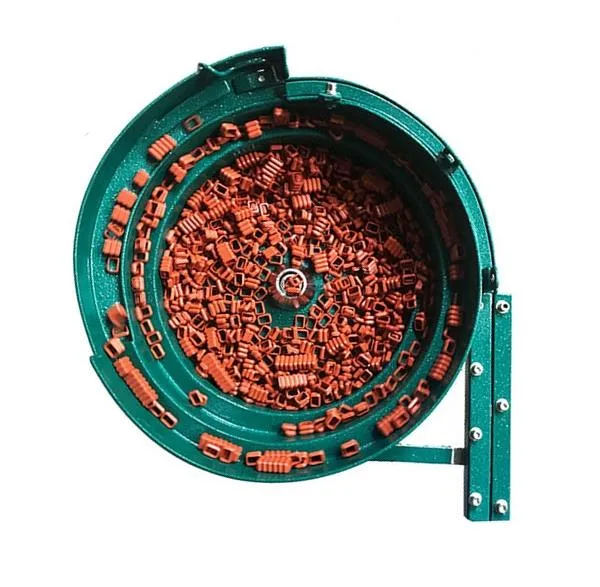

Vibratory Feeder Bowl for Rubber Vibrating Feeder Price

Description

Basic Info

| Model NO. | Vibratory Feeder Bowl for Rubber |

| After-sales Service | Support |

| Warranty | 1 Year |

| Type | Electromagnetic Vibrating Feeder |

| Movement Mode | Linear |

| Usage | Gravel Field, Metallurgy, Building Materials, Chemical Industry |

| Appearance | Open-Type |

| Max Feeding (mm) | Customized |

| Capacity(t/h) | 80-150 |

| Motor Power(kw) | 1~10 |

| Installation Slope | Customized |

| Chute size(mm) | Customized |

| Overall Dimension | Customized |

| Lead Time | 7-14 Days |

| Transport Package | Plywood |

| Specification | SS201 |

| Trademark | SWOER |

| Origin | China |

| Production Capacity | 100 Sets/ Month |

Product Description

SWOER Oil Proof Technology:

Perhaps you are confronted with such a problem: How can I feed the rubber part well? Rubber parts contain some oil, which will make the bowl oily, and as the time goes by, the bowl bottom also becomes oily and to some extent, has a bad unsatifactory influence on the bowl performance, even the rubber part can't move on the track!But don't worry, SWOER always and successfully makes vibratory bowl feeder for rubber part, like rubber band, rubber plug etc.

1. Product Information

Name: vibratory bowl feeder for rubber part

Brand: SWOER

Material: top bowl--- 201 stainless steel

Place of Origin: Guangdong, China(Mainland)

Volatage: 0-260V

Frequency: 40-400Hz

Feedrate: 50-55pcs/min

Part: top bowl, feeder drive, linear feeder, controller, hopper, baseboard, conveyor, sensor, air tube, etc.Lead time:7-15 daysPayment:T/T,L/C,Paypal

2. Features

1.Exciting vibration force and power are well matched, vibration force is large, the weight of the body is light, small volume, low mechanical noise;

2.Adjustable& flexible Vibration frequency;

3.Various model, can be customized.

4.SWOER has its own proprietary oil proof technology ,can help you effectively prevent the oil problem.

Purchasing Process

Step 1:

1. Buyers provide physical pictures, sizes and materials;

2. Buyers provide the order and direction of discharging materials.

3. Buyers provide discharging speed;

4. Counterclockwise or clockwise;

5. Confirm if you need linear feeder, hopper, baseboard and sound-proof cover.

Step 2: Seller Evaluation FeedbackMaterial (returned to the buyer with the vibrating feeder) should be used for adjusting the vibrating feeder.

Step 3: After payment and delivery

1. Sellers begin to order and make the down payment.2. Video shooting on the test machine;

3. The buyer is satisfied and make the final payment.

4. Sellers pack wooden boxes and deliver goods by logistics.

Factory Overview

Our Contact