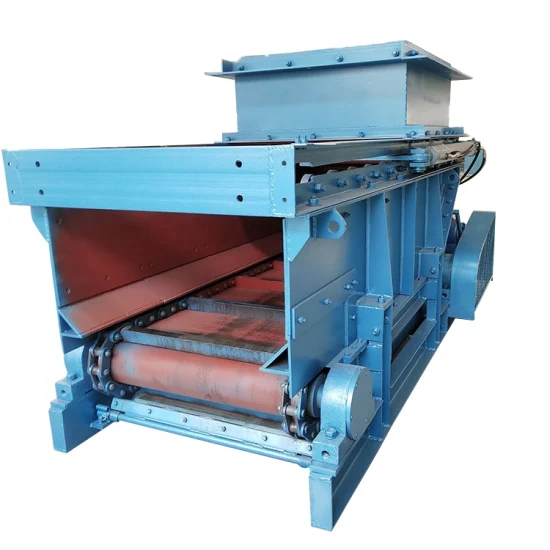

Heavy Duty Apron Feeder Plate Feeder with Large Working Capacity for Bulk Material Transport

Description

Basic Info

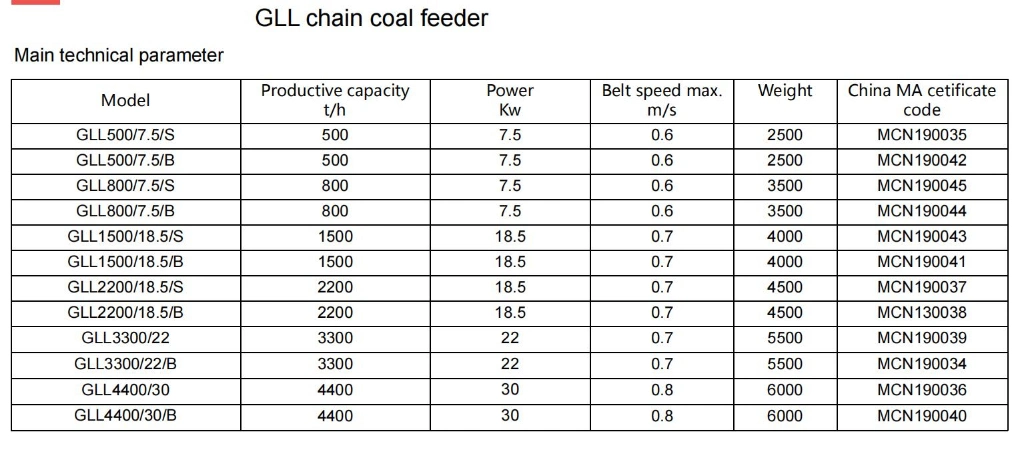

| Capacity(t/h) | 500 Ton-4400 Ton Per Hour |

| Motor Power(kw) | 7.5kw-30kw |

| Transport Package | Naked |

| Trademark | Kuangan |

| Origin | Shandong |

| Production Capacity | 500pieces/Month |

Product Description

GLL series Chain type scraper feederThe material in the bin enters the box body through the funnel frame and falls on the bottom plate and the plate chain scraper; When the driving drum begins to rotate driven by external power, it drives the plate chain to move, and the plate chain drives the scraper to drive the material on the bottom plate to guide the material outlet. The scraper in operation turns back after discharging at the outlet, and the material is continuously discharged from the outlet, thus completing the feeding process. A sweeper installed in the direction of the roller sweeps the material stuck to the scraper to avoid material scattering on the return side. Changing the size of the inlet can be achieved by adjusting the opening of the gate; To change the feed quantity, the speed of the plate chain can be changed by adjusting the speed of the output shaft of the CVT reducer, so as to change the feed quantity. To change the amount of feed, you can also change the motor speed by selecting a frequency converter, thus changing the amount of feed.

GLD series Belt type coal feeder

The coal feeding of belt feeder depends on the friction between the belt belt and the coal sill to feed the coal to the coal receiving equipment, so as to realize the work of belt feeder. Due to the need for friction, the belt speed of belt feeder should not be too high, otherwise it is easy to have relative sliding between the belt and the coal, which may lead to the failure of the coal feeding.GLW series K type plate feederThis series feeder, namely reciprocating feeder, consists of chassis, transmission platform, funnel, gate, connecting rod and the roller and so on its transmission principle: when the motor start, the elastic coupling, gear reducer, crank connecting rod device drag tilting chassis on the roller as a straight line reciprocating movement, the material evenly discharged to the transport machinery, or other screening equipment. This feeder has a variety of combination types, such as funnel, valve with adjustment and funnel, gate without adjustment, etc. When conveying hard materials, consider adding a liner at the bottom of the tank.

Prev: Good Quality Shaftless Screw Conveyor

Next: Professional Shaftless Screw Conveyor for Wastewater Treatment

Our Contact