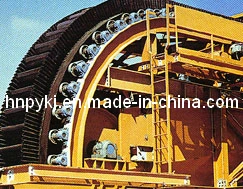

Flexowell Incline Corrugated Sidewall Belt Conveyor (DJ)

Introduction Sidewall belt conveyors are the best solution for horizontal, sloping or vertical product transport. It ado

Description

Basic Info

| Model NO. | DJ |

| Color | Multi Color |

| Customized | Customized |

| Condition | New |

| Material | Carbon Steel or Stainless Steel |

| Load Capacity | 11-711m3/T |

| Width | 500, 650, 800, 1000, 1200, 1400mm |

| Angle of Inclination | 30/45/60/90 Degree |

| Standards | ISO9001: 2008 |

| Belt Type | Corrugated Wall and Horizontal Baffle |

| Mining Object | Metallic and Non-Metallic Ore Excavator |

| Transport Package | as Customers′requirements |

| Trademark | PK |

| Origin | Henan, China (Mainland) |

| HS Code | 8428200000 |

| Production Capacity | 3000sets/Year |

Product Description

IntroductionSidewall belt conveyors are the best solution for horizontal, sloping or vertical product transport. It adopts high quality conveyor belt with corrugated sidewall and horizontal baffle. Sidewall belt conveyor is widely applied in coal and wood-chip fired power stations, underground mining (coal and ore),steel industry, ship loading and unloading, foundry plants, silo feeding industry, waste recycling, soil purification and water treatment, etc.

Advantages and Features

1.No spillage with steep angle conveying,long lifespan

2.Larger production grain sizes can be handled

3.Reduced energy consumption to save money for you

4.Able to conveyor material at any angles up to 90 degree to save space for you

5.Higher conveyance capacity

6.Extremely high stability is provided in the traverse direction, good longitudinal flexibility

7.Low maintenance requirements

8.Hot vulcanization provides 5 times greater adhesion between the belt and sidewall, eliminating the need for bolting the sidewall to the base belt.

9.Can be sealed and environmental friendly

Technical parameter

| Belt width (mm) | Height of side way (mm) | Distance between baffles (mm) | Capacity Qv(m³ /h)(mm) | Max materials size and belt speed(sec) | Power (Kw) | Angle of inclination(° ) |

| 500 | 80 | 126 | 11 | 1.0/50 | 15~18.5 | 90 |

| 252 | - | |||||

| 100 | 126 | 16 | 1.0/55 | |||

| 252 | - | |||||

| 120 | 126 | 24 | 1.0/60 | |||

| 252 | - | |||||

| 378 | - | |||||

| 650 | 100 | 126 | 23 | 1.25/55 | 1.5~22 | 90 |

| 252 | -- | |||||

| 120 | 126 | 34 | 1.25/60 | |||

| 252 | -- | |||||

| 378 | -- | |||||

| 160 | 252 | 25 | 1.25/80 | |||

| 378 | - | |||||

| 800 | 120 | 126 | 46 | 1.25/60 | 2.2~45 | 90 |

| 252 | -- | |||||

| 378 | -- | |||||

| 160 | 252 | 34 | 1.25/80 | |||

| 378 | - | |||||

| 200 | 252 | 55 | 1.25/100 | |||

| 378 | 36 | |||||

| 504 | - | |||||

| 1000 | 160 | 252 | 45 | 1.25/80 | 4.0~75 | 90 |

| 378 | - | |||||

| 200 | 252 | 75 | 1.25/100 | |||

| 378 | 48 | |||||

| 504 | - | |||||

| 240 | 252 | 111 | 1.25/140 | |||

| 378 | 73 | |||||

| 504 | - |

Factory pictures:

Prev: Zambia Food Granules Inclined DN159 Tubular Screw Conveyor

Next: Rotating Helical Screw Tubular Conveyor for Bulk Material Handling

Our Contact

Send now