Conveyor Belt Repair Rubber Vulcanizing Press Machine

Product Description Conveyor Belt Repair Rubber Vulcanizing Press Machine The pressure water bladders : 1. The weight is

Description

Basic Info

| Model NO. | ZLJ--2000x830 |

| Certification | CE, ISO |

| Condition | New |

| Customized | Customized |

| Automatic Grade | Automatic |

| Structure | Splicer |

| Heating Way | Electric |

| Type of Tire Machinery | Belts Jointing Vulcanizer |

| Delivery Time | Within 30days |

| Colors | According to Customer |

| Transport Package | Standard Wooden Case Packing |

| Specification | Customized |

| Trademark | BOJIA |

| Origin | Qingdao China |

| HS Code | 8477800 |

| Production Capacity | 50 Piece/Months |

Product Description

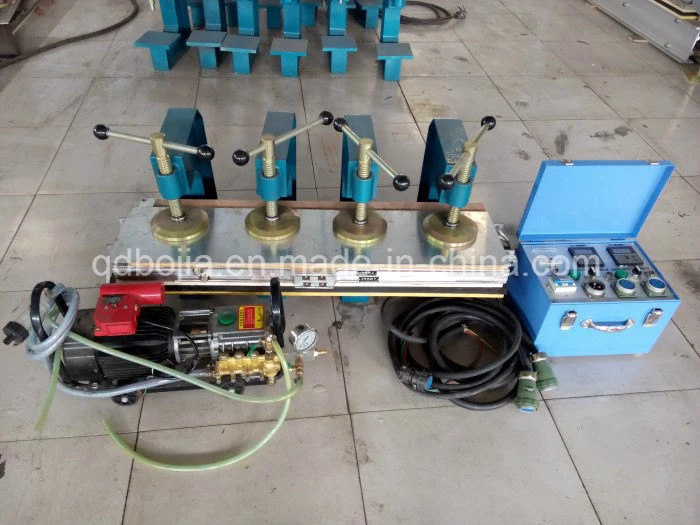

Conveyor Belt Repair Rubber Vulcanizing Press Machine

The pressure water bladders :

1. The weight is very light than the normal ones, it is about a quarter of the normal ones

2. With large amplitude expansion: when pressing, the screws beside on the machine can fixed easily by hand.

3. Uniform pressure, and 70-100mm bigger around the hot plate than the common machines.

4. With big pressure at about 3.0Mpa

5. No leaking: no leaking even in the high pressure and long working time

Heating system with soft mat:Our heating plate is adopt "carpet heating" with soft surface ,uniform heating of conveyor belt and energy conservation.

Our conveyor splicing belt adopts Canadian technology and please finds the advantages as follow.

1. With light-weight and easy to hand and move.

2. Quickly increase temperature, uniform heating.

3. Waterproof: Can be used in damp or water environment, not conduct electricity

Main Parameter:

| Model | Width of rubber belt to be joined-up (mm) | Total Power(KW) | Weight of heaviest part (Kg) | Overall dimensions LxWxH(mm) | Total weight (kg) | Control box |

| ZLJ--1200 | 1200 | 16.5 | 69.3 | 1680×830×710 | 900 | 1 |

| ZLJ--1600 | 1600 | 21.1 | 89.7 | 2140×830×800 | 1320 | 1 |

| ZLJ--1800 | 1800 | 23.3 | 89.7 | 2300×830×850 | 1480 | 1 |

The main parts of vulcanization joint machine are made of high strength aluminum alloy. It is equipped with automatic explosion-proof electric cabinet and has 0-2Mpa even pressure offered by the pressure system, so it is easily operated, portably carries. It warms up by electric heating element, so it works stably with high thermal efficiency and homogeneous temperature. Now it has been widely used in the joint and patch of vuloanization machine in the field of metallurgy, mining, cerement, electric power, wharf, building materials, chemical industry etc.FAQ:

1

Q:Are you a factory or trading company?

A:We are a professional manufacturer and running our own factory for more than 10 years .2

Q:Where is your factory?How can I visit ?

A:Our factory located in qingdao city.You can fly to QINGDAO LIUTING airport,then we can pick you up to our factory for your visiting.We are looking forward to your visiting.3

Q:How does your factory control the quality of machines and after sales service?

A:Our machines have passed CE,ISO,SGS certification,with best quality and reasonable price.All our machines have 1 year guarantee, will be provided for a lifetime maintenance.4.What's your payment term?

A:Common is 30% deposit by T/T,the balance paid against shipping documentsOr L/C at sight.5

Q:Can you design new product for us?

A:we have a professional development team that can make new products according to your requirements.6. Delivery time of the rubber machines?This is specially designed machine according to your specific requirement. From engineer designing to production completion, it needs about 25 to 35 days. 7. What does your factory do regarding quality control? We pay much more attention to the quality controlling from the very beginning to the end of production. Every machine will be fully assembled and carefully tested before shipment. 8. What's the machine quality guarantee?we provide one year warrenty for our machines.We choose the world's famous brand of components to keep our machine in perfect working condition. 9. Are you able to provide the installation and commissioning of machines overseas? How long will it take?Yes, we can supply overseas service and technical support but customer needs to pay for the cost of the installation. Small machine usually takes within 2~3 days. Big plant usually takes about 30 days. 10. How can I trust you to deliver the right machine as I ordered?We will absolutely deliver a good quality machine as we discussed and confirmed in the order.The core of our company culture is innovation, quality, integrity and efficiency. Also we have had much good cooperation with world famous rubber production manufacturers. If you come to our factory, we can show you're the user around us. Packaging Equipment painting completed before delivery, and then wrapped with stretch film, to protect the painting surface, we use wooden packaging outside.The key parts of the machine, such as electronic control box, will be wrapped by shockproof packaging materials, and then packed in wooden cases.There are 15 experienced engineers and 108 skilled workers in our company, guaranteeing delivery on time as stipulated in the contract. At the same time, the company established a long-term cooperative relation with Cosco, for ensuring the goods arriving port on time.

Our Services Our engineers can design target machines for customers and send them the drawing to confirm. We are always on the side of saving your cost.In the process of production, we will take photos and send to customers for their track the progress.Documents such as packing list, commercial invoice, and bill of lading etc. will be sent after the delivery.We could supply free English foundation DWG, installation drawing, user guide, maintenance manual and part drawing.We supply overseas engineer service and do our best to teach your workers operate the machine themselves.

Our Contact

Send now