Circular Vibrate Sieve Gold Washing Trommel Screen

Overview Circular Vibrate Sieve Gold Washing Trommel Screen Product Description Vibrating screen is a traditional screen

Description

Basic Info

| Model NO. | VS150 |

| Shaft Number | Single |

| Running Track | Linear Vibrating Screen |

| Supporting Device | Coil Spring |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| Capicity | 150t/H |

| Transport Package | Strong Film Package |

| Trademark | ETERNE |

| Origin | China |

| Production Capacity | 200 |

Product Description

Circular Vibrate Sieve Gold Washing Trommel Screen

Product Description

Vibrating screen is a traditional screening equipment,is designed specifically for material stone screening in quarry, but also used for coal preparation, mineral processing, building materials, electricity and chemical departments for production classification.

There are many types vibrating screen machinery,the most applicable in alluvial gold type is eccentric shaft type orvibrating motor type.

Product Parameters

| Model | VS150 | VS200 | VS300 |

| Capacity | 150T/H | 200T/H | 300T/H |

| Feeding Size | 0-300mm | 0-300mm | 0-300mm |

| Screen Size | 4200*1700mm | 5300*1900mm | 6000*2200mm |

| Weight | 3.5T | 4.2T | 5T |

Detailed Photos1) VS series gold washing plant is designed according to your specific mining conditions and requirements. 2) A feeding system with a lime-soil funnel feeder, and the water spray pipe in the funnel sprays water to the soil.3) Heavy-duty clay scrubber with internal high-pressure water spray pipes for separating hard clay. (If needed)

4) Double sieve sieve sieve with NSK bearings and high-pressure water spray pipes on both sides for cleaning, sieving and separation.5) Double gold recovery system to ensure the highest gold recovery rate (up to 98%).

6) The water supply system is equipped with multiple sets of high-power submersible mud pumps, hoses, valves, etc.

7) The power system of diesel generator, including all batteries, cables and wires. 8) Multiple sets of heavy-duty miningtires with traction mechanism, with sufficient mobility and portability.9) Gold refinery, which produces the final product of gold bars.

10) Easy to install, operate and maintain.

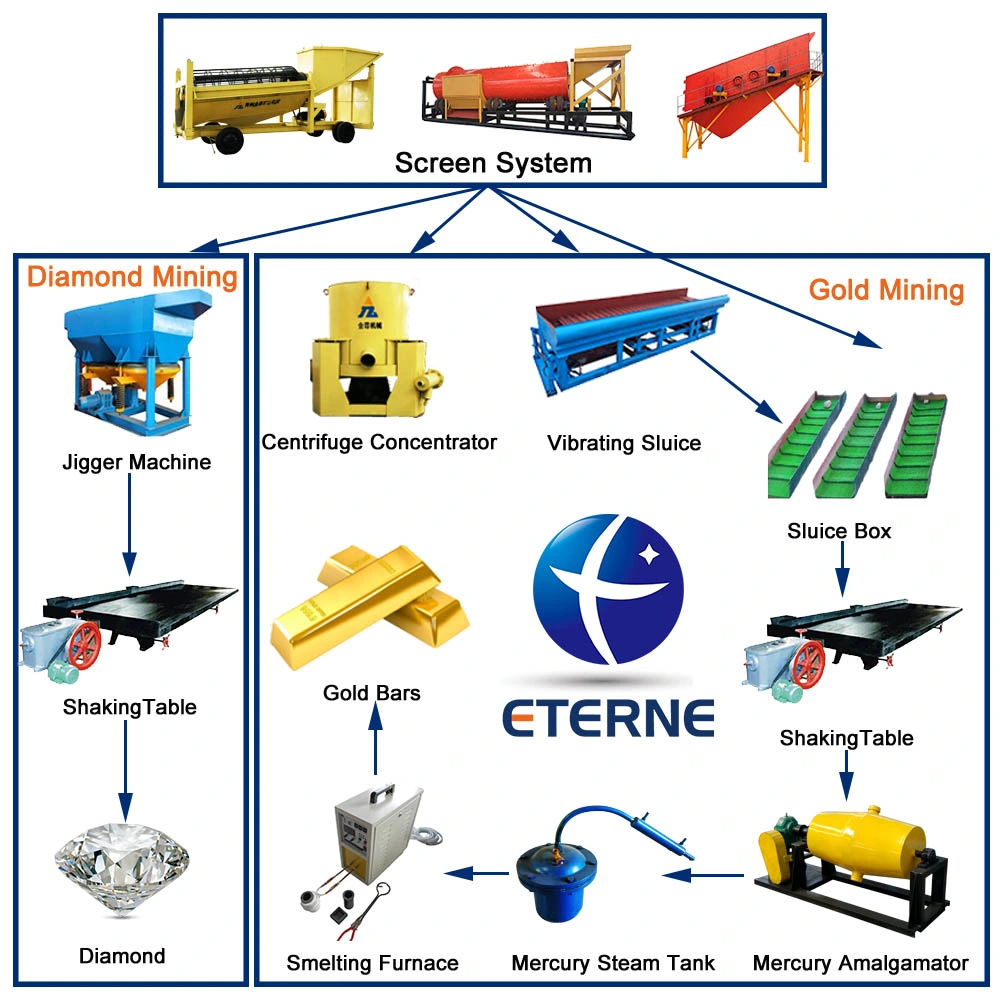

Related products

FAQ1. Are you factory?A1.Yes, established in 2002, over 15 years factory.Q2. How big are you?A2.In total 6 work shops, 15,000, office 3000, 80 workers.Q3. What equipment do you build?A3Specialized in alluvial/placer gold/diamond mining equipment.Q4. Whats the capacity of the gold/diamond mining equipmentA4.from 5TPH to 450TPH.Q5. What brand engine/diesel generator do you use?A5.As required.

Our Contact

Send now