Apron Feeder Weight Feeder for Coal

Belt coal feeder Application and characteristics: (1) Belt type coal feeder (also known as belt coal feeder) is mainly u

Description

Basic Info

| Model NO. | SSI-DGJ |

| Max Feeding (mm) | 200mm |

| Capacity(t/h) | Determined According to The Project |

| Motor Power(kw) | Determined According to The Project |

| Installation Slope | 0 |

| Chute size(mm) | Determined According to The Project |

| Overall Dimension | Determined According to The Project |

| Feature | Reliable and High Performance |

| Transport Package | Nude |

| Specification | Determined according to the project |

| Trademark | SSI |

| Origin | China |

| HS Code | 8419609090 |

| Production Capacity | 100 Sets / Year |

Product Description

Belt coal feederApplication and characteristics:(1) Belt type coal feeder (also known as belt coal feeder) is mainly used for discharging the material from the hopper of car dumper,After buffering, it is evenly and continuously distributed to the belt conveyor, which is then sent to the coal bunker or raw coal hopper of the boiler.

(2) The belt coal feeder produced by our company has the characteristics of low belt speed, no noise, small center distance between head and tail drum, large output range and convenient maintenance,The head drum, tail drum, upper parallel bearing roller and rubber surface roller are all cast with glue on the surface of the cylinder, which improves the service life of the ordinary rubber coated roller,At the same time, it has the function of shock absorption.At the same time, it can be used for coal production.

At present, the belt coal feeder is widely used in the thermal power plant with car dumper, and the belt coal feeder can also be used as a short distance belt conveyor in the coal conveying system.

Structure and composition:

The belt type coal feeder is mainly composed of driving device, belt, guide groove, head drum, turning drum, upper idler, lower idler, support, head funnel, cleaning device and screw tension device;The mobile belt coal feeder is powered by electric push rod, equipped with walking device, rail cleaning device, track and maintenance moving out device, etc.; the regulating device at the outlet of the guide chute can control the size of coal feeding; the upper idler of the working belt generally adopts parallel roller, or according to the actual situation, the groove roller can be used according to the actual situation,The change direction roller is used as the bearing roller;The belt type coal feeder under the dumper is used. The belt supporting plate is installed between the idlers at the blanking opening to prevent the belt longitudinal tearing caused by sharp objects in the material;For the belt coal feeder that requires increasing output, our company adopts the form of installing fixed side baffles within the range of all the length of the belt coal feeder and making it into a coal retaining groove;The use of screw tension device is light and flexible, easy to adjust; in short, we will fully consider various factors, design and manufacture more perfect products to serve you.

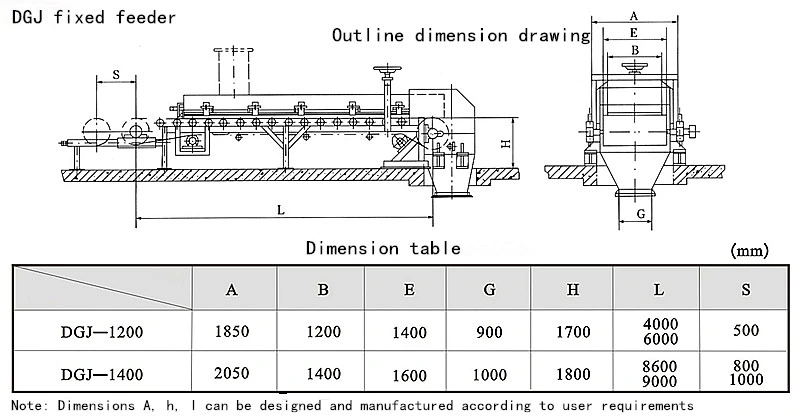

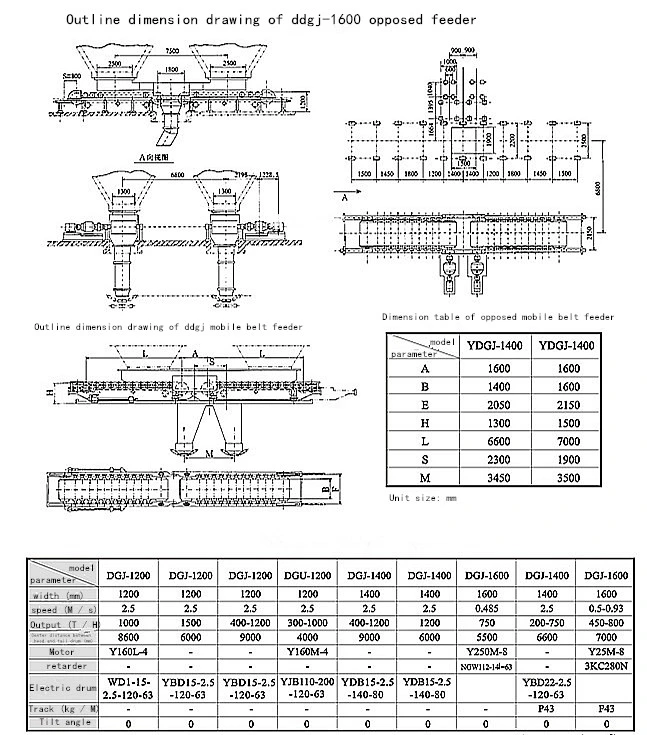

Product classification and model:

There are three types of belt coal feeders: single fixed DGJ type, opposite fixed type ddgj type and mobile opposite type ydgj type, which are divided into various specifications according to bandwidth series.

Each kind of drum can be divided into several varieties because of different driving, output, belt speed, center distance between head and tail drum and so on.

Order notice:

- Please indicate the specification, model and quantity when ordering.

- Please provide technical parameters.

Brief introduction of the company's manufacturing capacity

The company's headquarters, technology and sales are located in Lingang New Area of China (Shanghai) pilot free trade zone,The company's manufacture base is located in Tonglu county, Zhejiang Province, which is known as "the most beautiful county in China". It is 65 kilometers away from Hangzhou city and 60 kilometers away from Qiandao Lake. The transportation to Tonglu county from other places is very convenient. No matter by railway, highway or waterway. The manufacture base has a total plant area of around 30000 square meters and workshop is equipped with more than 300 sets of various advance manufacture equipment, including 20 sets of CNC precision vertical lathe MODEL: SMVTM12000×50/150, CNC vertical lathe MODEL:DVT8000×30/32, CNC horizontal lathe, MODEL: CK61315×125/32, CNC horizontal lathe MODEL:CK61200×80/32, CNC Grounding boring and milling machine MODEL:TJK6920,etc.Most of the parts are machined by using CNC machine equipment. Theis is a hot treatment furnace with size 10.5m×8m×8m. The manufacture base also equipped with lifting capacity of 25t, 50t, 100t, 200t overhead crane to handle heavy workpiece and assembly work.

Products and services available

Material handling equipment

Storage equipment

Conveying equipment

Feeding equipment

Component of conveying system

Belt conveyor parts

Large and medium sized finishing parts

If you need above products, please contact us!

Shanghai Sunshine Industrial Technology Co. , Ltd.

Prev: Rubber PVC Conveyor Belt Splicing Joint Press Machine

Next: Apron Feeder, Stone Crushing Vibration Feeder, Mining Industry Feeder

Our Contact

Send now